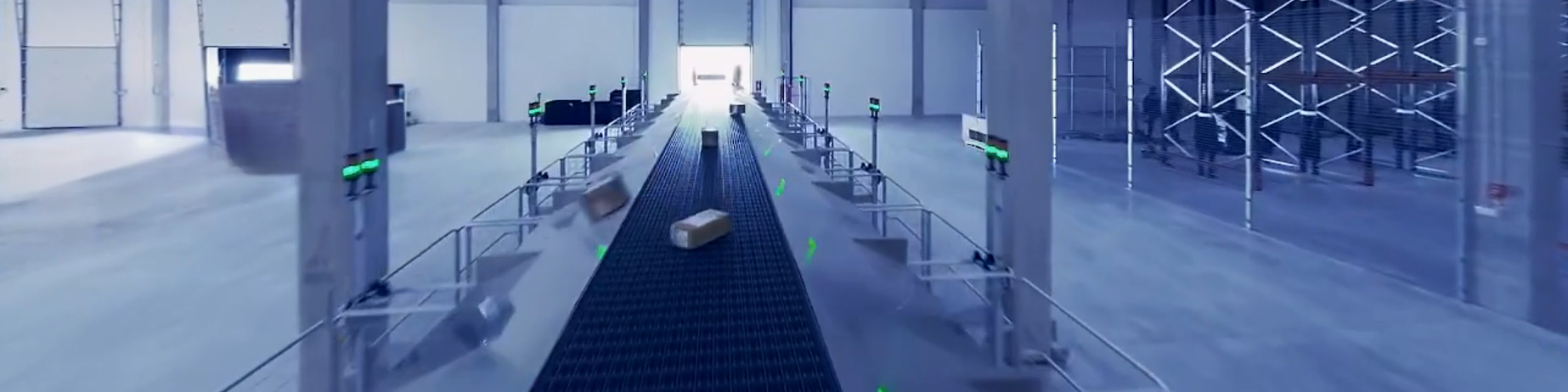

The main task of the sorting system is to transport packages to their appropriate destinations where shipment to specific locations takes place.

The system is capable of identifying a package by scanning the barcode placed on it, and after communicating with the WMS system, it can send the product to the appropriate location based on the information received from the higher-level system.

Advanced sorter, using a scanning tunnel, reads the label with a barcode placed anywhere on the product. After exchanging information with the higher-level WMS system, it directs the product to the appropriate destination.

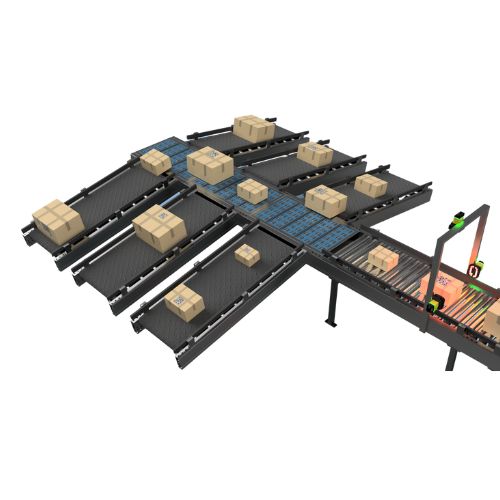

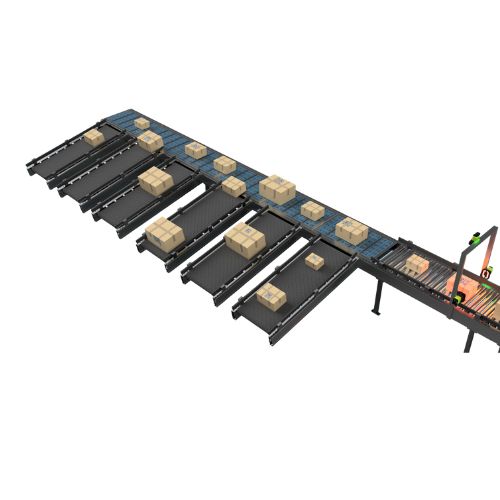

The number of feeding lines, loading stations, and destinations is tailored to individual customer requirements.

Contact us and let us help you choose the right sorting system.

Specification:

- Throughput up to 5000-7000 products per hour

- Belt widths: 432, 685 or 1016 mm

- Weight of item: from 0.01 kg to 30 kg

- Dimensions of item: from 100x150x10 mm up to 800x800x800 mm

- Supported products: envelopes, polybags, cartons, tires

- Contains an automated barcode scanning system with the possibility of image capture of each parcel

- Can be upgraded with the dimensioning and weighing feature

- Final specification including sorting technology, infeed lines, length and number of chutes can be tailored to customer’s needs.

We are a provider of a wide range of sorting solutions tailored to our clients' needs. We offer expert advice and support in developing the right concept for each application. Our portfolio includes sorting technology such as roller top sorters, narrow belt sorters, shoe sorters, pop-up sorters and cross belt sorters. Each system is designed to ensure maximum efficiency, flexibility, and seamless integration into existing material handling operations.

“Smart sorting. Smarter logistics.”